STEEL

Carbon Upcycling is a slag beneficiation solution for the steel industry.

We offtake and enhance low-grade iron and steel slags into valuable low-carbon cement products.

20%

CO2 capture1:1

Slag for cement

*All numbers are represented as maximums

The iron and steel industry is undergoing a significant transformation. Manufacturers are rapidly transitioning to electric arc furnaces and hydrogen reduction processes to meet global demands for low-carbon steel. However, as the industry decarbonizes, the byproducts it once produced can no longer be used in high-value applications like cement - until now.

For every 1 tonne of steel,

~1 tonne of steel slag is produced

~1 tonne of steel slag is produced

Industrial Circularity:

From liability to asset

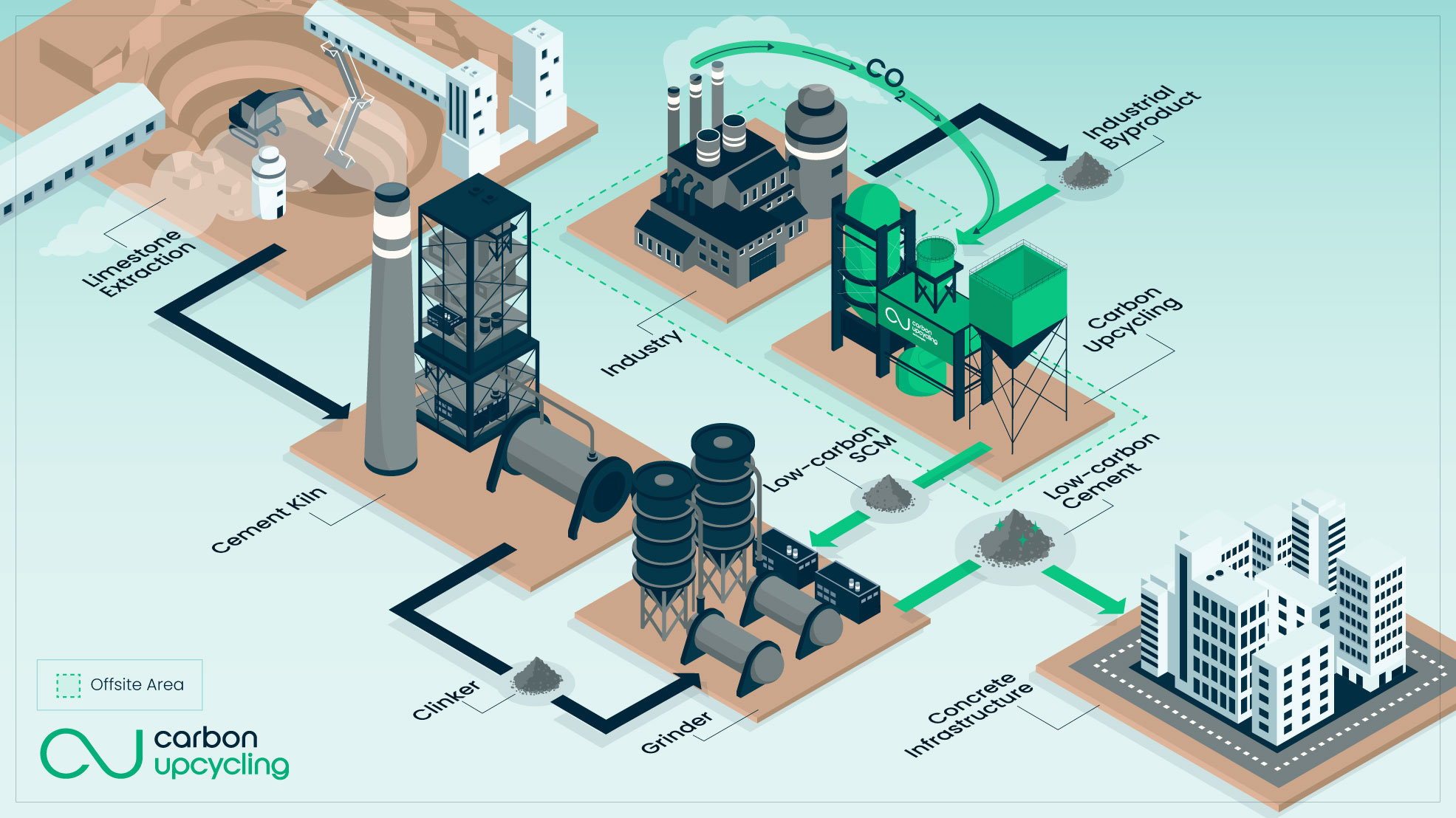

The relationship between the steel and cement industries exemplifies the circular economy in action. Historically, blast furnace slag—a byproduct of coal-based iron making —has been a valuable resource for cement manufacturers, enhancing concrete strength and reducing emissions from raw materials. However, as coal phases out, so does the availability of this critical byproduct.

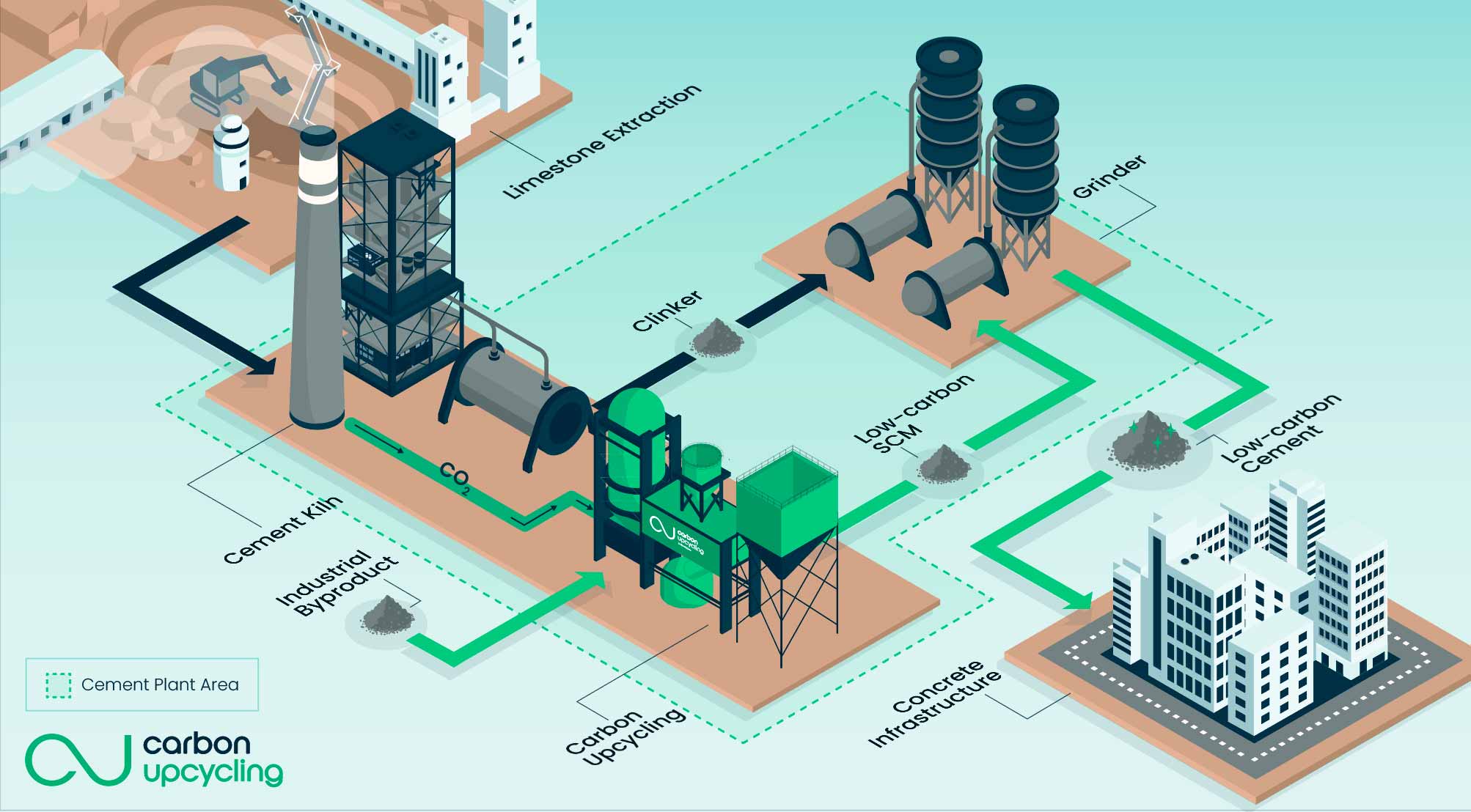

Carbon Upcycling is redefining this synergy by transforming emerging types of steel slags and legacy stockpiles into valuable cement products while capturing CO2 emissions. Our technology enhances steel slags to meet industry standards, utilizing point-source CO2 emissions to improve material performance. This process not only diverts waste from landfills but also creates a new revenue stream for steel producers while providing the cement industry with a reliable, low-carbon solution.

Featured: CRH Mississauga Cement Plant

Iron & Steel Slag Beneficiation

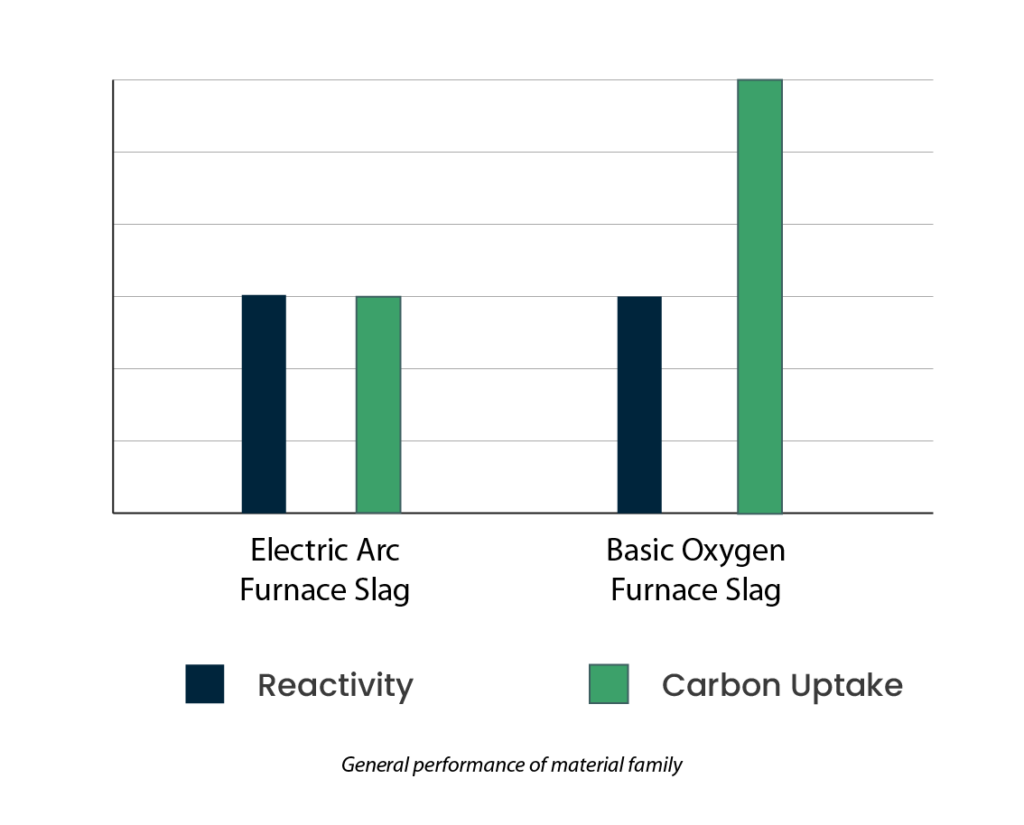

Non-blast furnace slags are largely inert due to their chemical composition. Our CUT CO2 system is able to enhance the reactivity of these new materials to meet the specifications necessary for cement.

Materials

- - Electric Arc Furnace slag

- - Basic Oxygen Furnace slag

- - Ladle slag

- - Blast Furance slag

Benefits

- • Works with the varying compositions of EAF slag

- • Increased material reactivity and strength

- • Carbonates assist with mitigating heavy metal leaching

- • Up to 20% carbon uptake

Full Stack Carbon Capture & Utilization

What takes nature years,

we accomplish in a few hours

One of the greatest barriers to carbon capture and storage is the cost of infrastructure to capture and transport CO2 and the need for stable geological deposits to store captured emissions. Carbon Upcycling offers an energy-efficient capture and utilization solution to permanently sequester and create value from captured carbon onsite.

The CUT CO2 system accelerates the process of carbon mineralization, locking away CO2 emissions in select materials while creating high-performance SCMs. We prepare the material to selectively uptake CO2 directly from point source emissions with concentrations as low as 4%.

Already have a carbon capture system installed? Our system can integrate into your current carbon capture project, providing a valuable offtake for your captured CO2.

Drag

Engage with Us

Our team collaborates with your operations and material recovery partners to upcycle alternative slag onsite or at our partner locations.

Onsite Project

Material Identification

- Identify potential materials in your portfolio and surrounding area

Basic Analysis

- Initial material composition analysis

- Report of material activation suitability (They send us material comp and we provide a report of suitability)

MACE Material Activation

- Small-scale material testing

- Comprehensive material report

- Mortar testing

- SAI

- ASR

- Water Demand

- Carbon Uptake

- TGA

- TGA

- Treated material sent back for your own testing

Medium & Large-scale Trials

- Material activation in industrial-scale system

- Material process optimization

Project Execution

- Project evaluation & feasibility studies

- Detailed design & engineering

- Technology integration

- Site operation

Material Offtake

Material Identification

- Identify potential materials in your portfolio and surrounding area

Basic Analysis

- Initial material composition analysis

- Report of material activation suitability (They send us material comp and we provide a report of suitability)

MACE Material Activation

- Small-scale material testing

- Comprehensive material report

- Mortar testing

- SAI

- ASR

- Water Demand

- Carbon Uptake

- TGA

Offtake Agreement

- Offtake Agreement