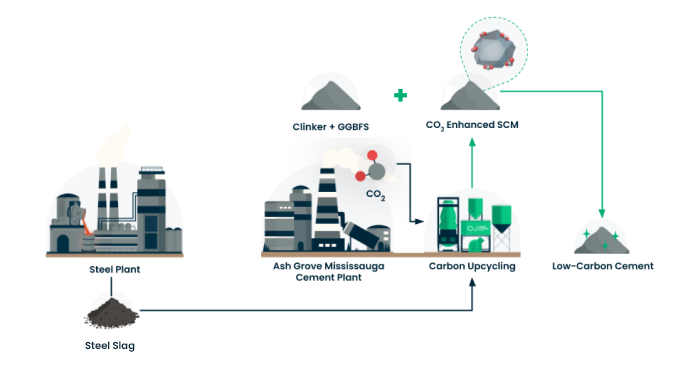

CRH Cement Plant

Mississauga, CA

Commercial Pilot

Ash Grove, a CRH Company

Alternative Steel Slag

"We have chosen to develop our existing partnership with Carbon Upcycling further as its technology solution aligns directly with our circular, zero-waste sustainability values. The cement plant integration we are supporting means this technology will be deployed at commercial scale in one of the largest cement plants in Canada, demonstrating a cost-effective, circularity-based method of producing low-carbon cement.”