CEMENT

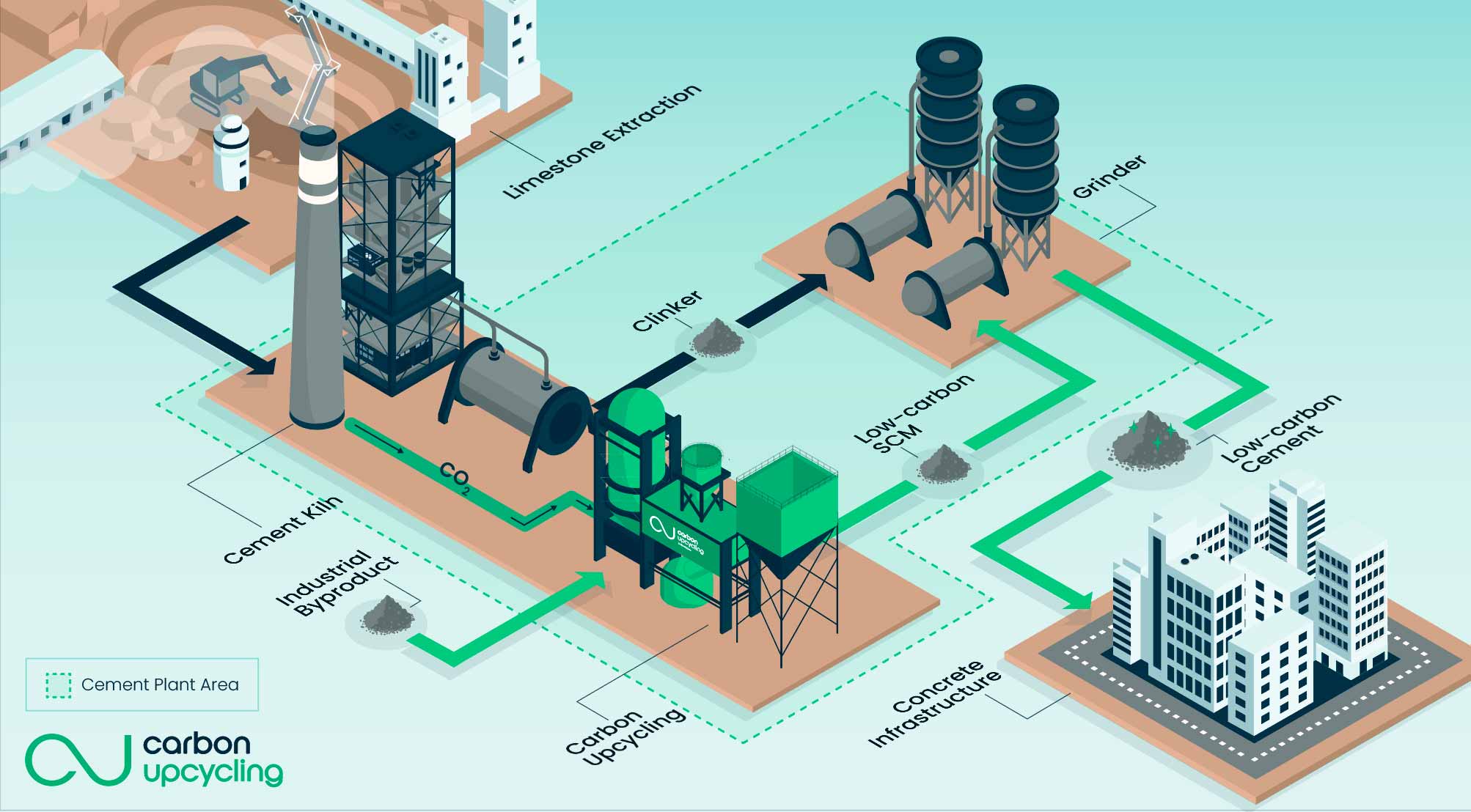

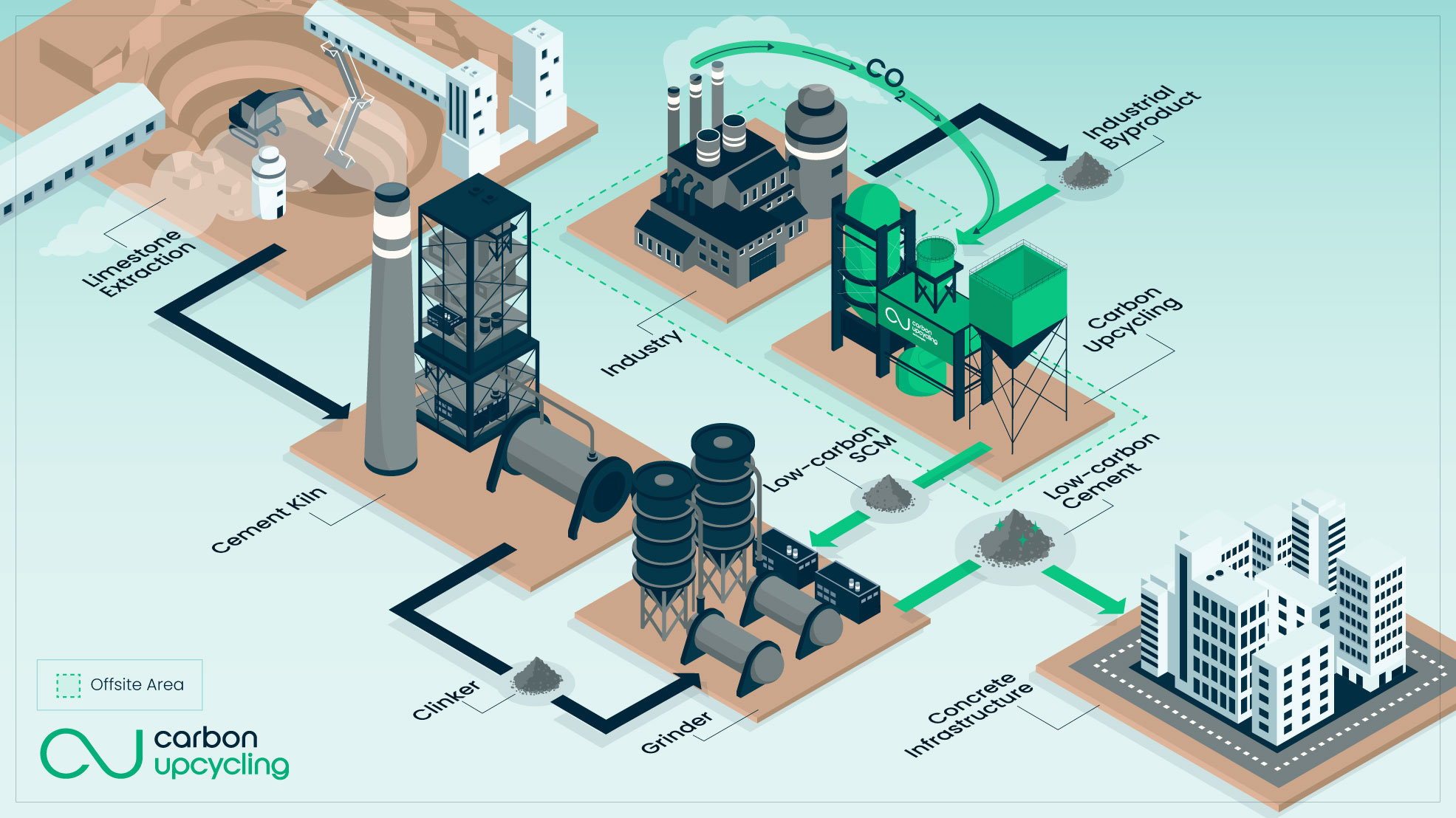

Carbon Upcycling is a SCM manufacturing technology for transforming carbon emissions and industrial byproducts into new local sources of low-carbon cementitious materials.

60%

Emissions reduction50%

Clinker replacement40%

Stronger concrete

*All numbers are represented maximums compared to traditional ordinary portland cement blends

The cement industry is at a crossroads. Manufacturers are faced with meeting an unprecedented global demand during a time of critical material shortages and growing pressure to decarbonize. As a result, manufacturers must innovate to secure their supply chains and find new ways to produce cement sustainably. Now is the time for manufacturers to set the foundation to thrive in the low-carbon future they are building.

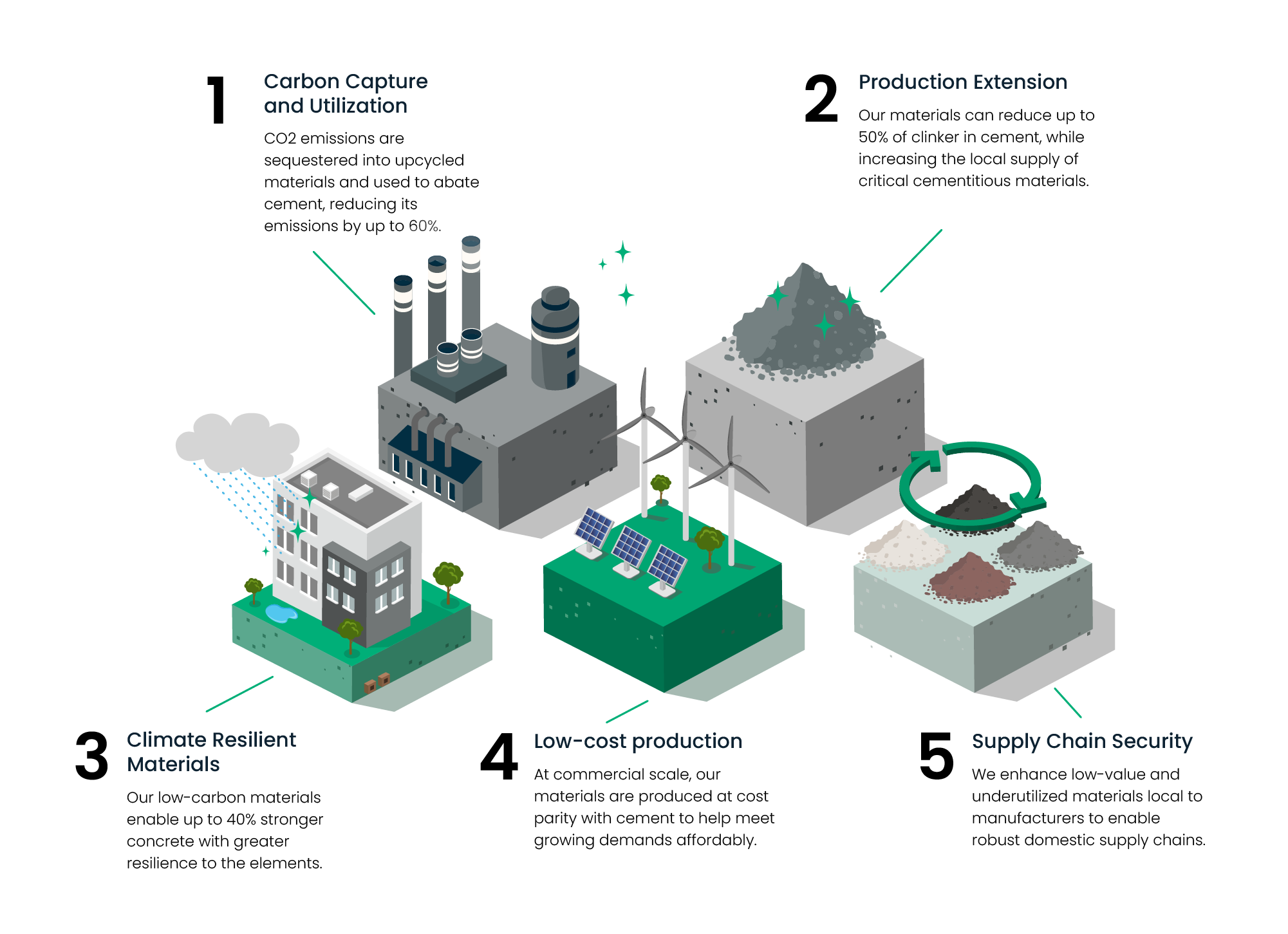

Carbon Upcycling provides five key pillars to help the cement industry achieve its 2030 climate targets while meeting growing demands for low-carbon cement.

SCMs:

A necessary lever for cement decarbonization

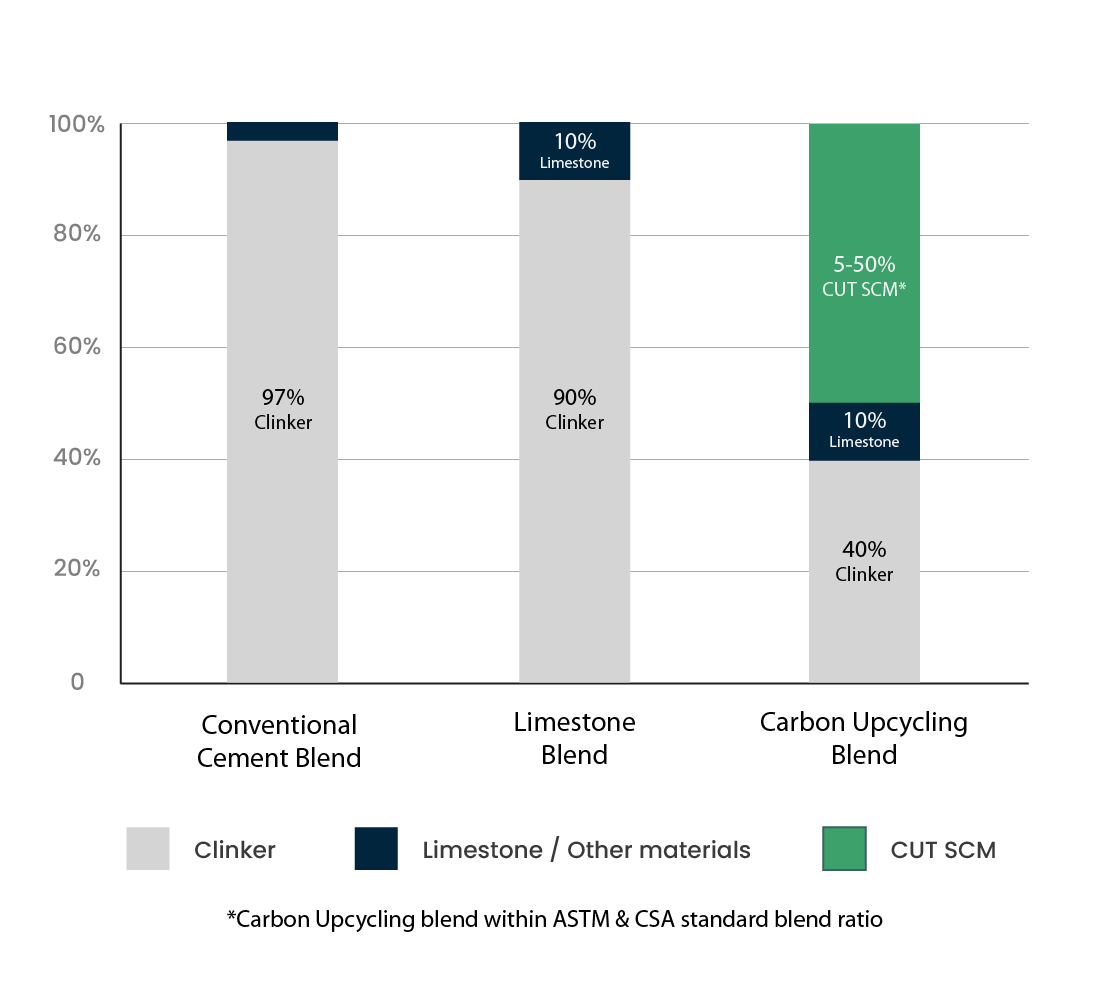

Decarbonizing cement is a chemistry problem where the majority of emissions come from the breakdown of limestone into clinker, the most carbon-intensive ingredient in cement.

Cement manufacturers have traditionally used supplementary cementitious materials (SCMs), such as fly ash from coal-fired power plants and blast furnace slag from coal-based ironmaking, to partially replace clinker in cement. This reduces emissions through abatement, enhances performance, and extends their supply of cement. As highlighted by the Portland Cement Association, SCMs are a critical lever to reaching net zero.

However, as domestic industries like utilities and steel phase out coal, the availability of traditional SCMs has dwindled significantly, causing North American and European manufacturers to rely on imports from overseas.

Unlocking the next generation

of domestic SCM's

of domestic SCM's

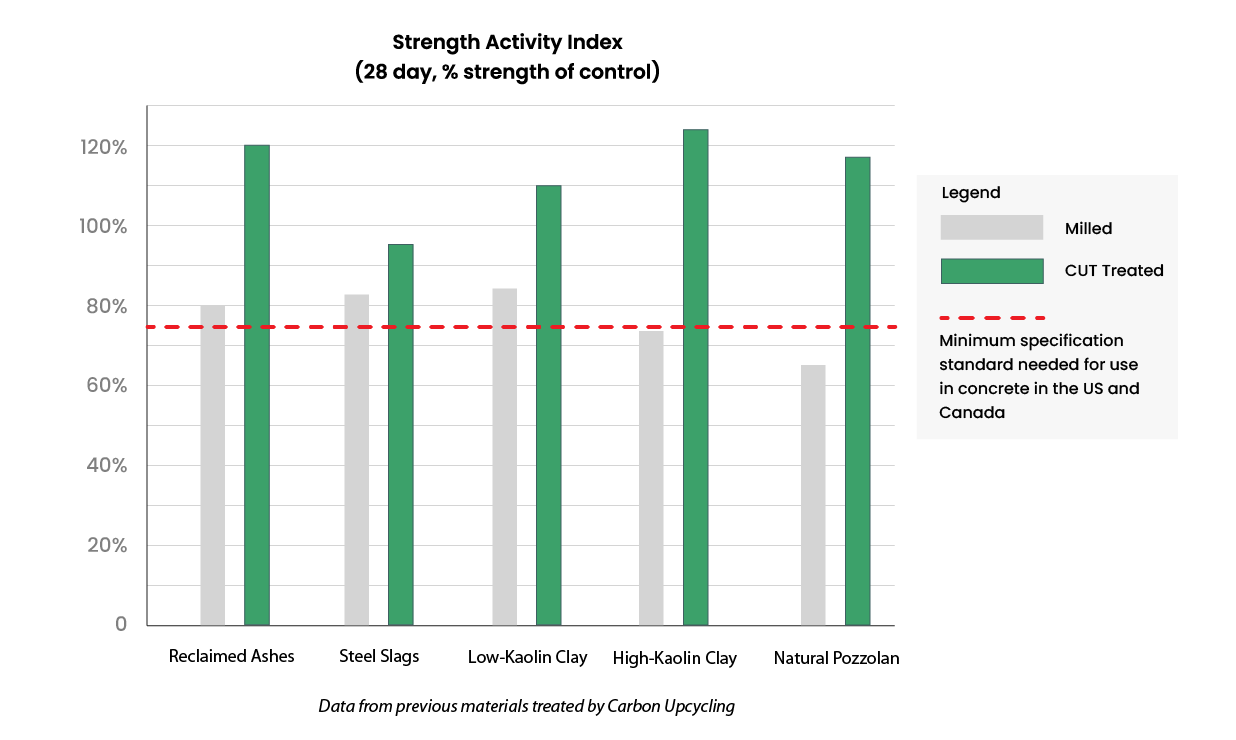

Carbon Upcycling taps into the billions of tonnes of underutilized materials available globally to create new sources of high-performance SCMs with the potential to capture CO2.

We focus on three main families of materials: legacy coal ash, steel slags, and clays. Our process enhances the reactivity of these materials to enable low-carbon cement blends that meet or exceed regulatory standards and create stronger, more climate-resilient concrete.

By enhancing these low-grade materials, we can provide locally sourced solutions tailored to your region.

Full Stack Carbon Capture & Utilization

What takes nature years,

we accomplish in a few hours

One of the greatest barriers to carbon capture and storage is the cost of infrastructure to capture and transport CO2 and the need for stable geological deposits to store captured emissions. Carbon Upcycling offers an energy-efficient capture and utilization solution to permanently sequester and create value from captured carbon onsite.

The CUT CO2 system accelerates the process of carbon mineralization, locking away CO2 emissions in select materials while creating high-performance SCMs. We prepare the material to selectively uptake CO2 directly from point source emissions with concentrations as low as 4%.

Already have a carbon capture system installed? Our system can integrate into your current carbon capture project, providing a valuable offtake for your captured CO2.

Drag

Engage with Us

From material identification to project implementation, we work with you to transform your operation and unlock a secure, low-carbon, local supply of SCMs.

Material Identification

- Identify potential materials in your portfolio and surrounding area

Basic Analysis

- Initial material composition analysis

- Report of material activation suitability (They send us material comp and we provide a report of suitability)

MACE Material Activation

- Small-scale material testing

- Comprehensive material report

- Mortar testing

- SAI

- ASR

- Water Demand

- Carbon Uptake

- TGA

- TGA

- Treated material sent back for your own testing

Medium & Large-scale Trials

- Material activation in industrial-scale system

- Material process optimization

Project Execution

- Project evaluation & feasibility studies

- Detailed design & engineering

- Technology integration

- Site operation